What is Steel Detailing?

If you’ve ever wondered about the intricate process behind turning engineering drawings into tangible steel structures, you’re in the right place. This article delves into the world of steel detailing, exploring its importance, challenges, and the vital role played by detailers in bringing construction projects to life. Whether you’re a seasoned professional or just starting to learn about this fascinating field, we hope you find this journey informative and inspiring.

Steel detailing

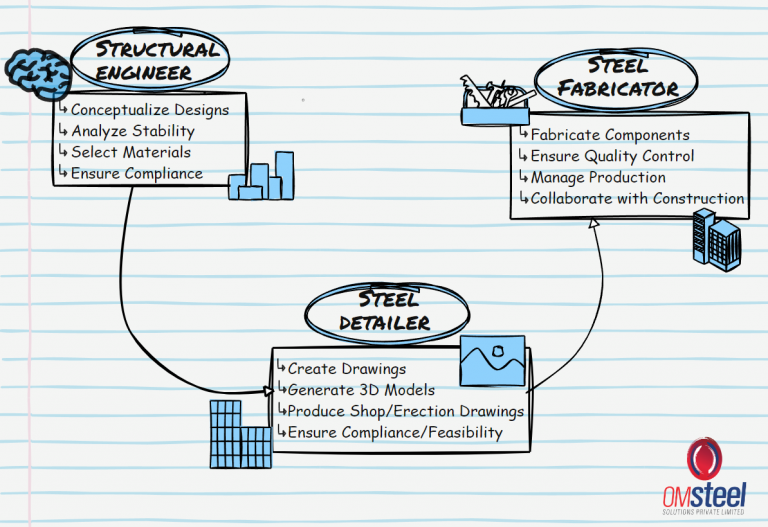

Structural steel detailing is the process of creating detailed drawings and documentation for the fabrication and construction of steel structures. It involves translating the structural engineering drawings, typically provided by an engineer or an architect, into detailed shop drawings and documentation that specify the dimensions, materials, connections, and other information necessary that can serve as a guide for steel fabricators and construction teams.

Precision is paramount in construction, where each steel component must be accurately cut, holes correctly aligned, welds seamlessly joined, and bolts securely fastened at their designated locations. It’s the responsibility of steel detailers to create precise drawings, ensuring that fabricators can manufacture the required steel components with accuracy and efficiency.

Role of steel detailer

What is a steel detailer OR what does a steel detailer do exactly?

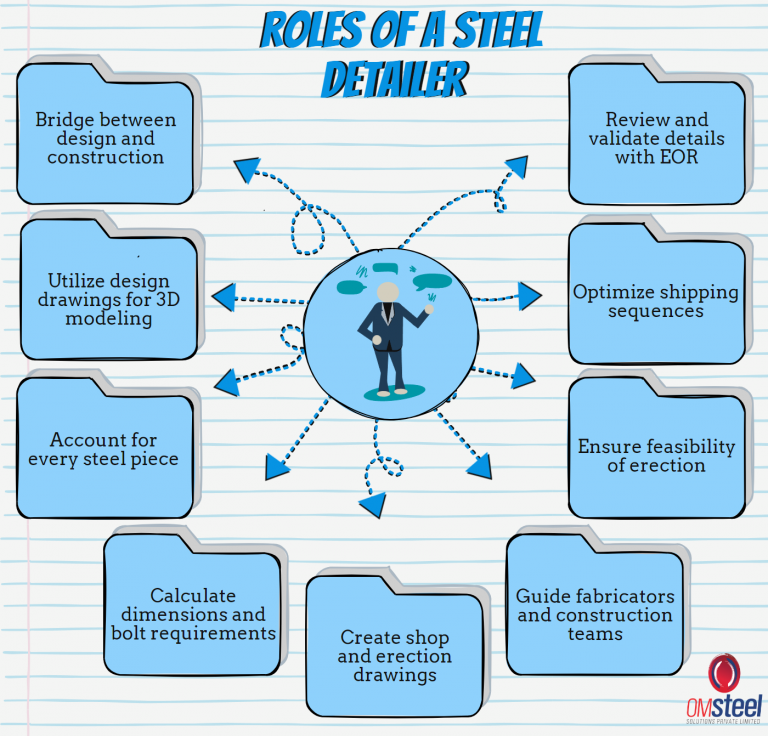

Steel detailers play a crucial role in the construction process, acting as the bridge between design concepts and tangible structures.

They begin by utilizing design drawings provided by structural engineers to create detailed 3D models of steel components. Once the model is complete, the detailer meticulously accounts for every piece, calculating the length of beams and columns, as well as the quantity and length of bolts for each hole.

They then translate this information into comprehensive shop drawings and erection drawings, which serve as guides for fabricators and construction teams.

Additionally, steel detailers are tasked with ensuring the feasibility of erection and optimizing shipping sequences to streamline the construction process. Before submitting the drawings for fabrication, they must review and validate all details with the engineer of record (EOR) to ensure compliance with design specifications and industry standards. Through their attention to detail and expertise in structural engineering principles, steel detailers contribute to the successful execution of construction projects.

What are shop drawings and erection drawings?

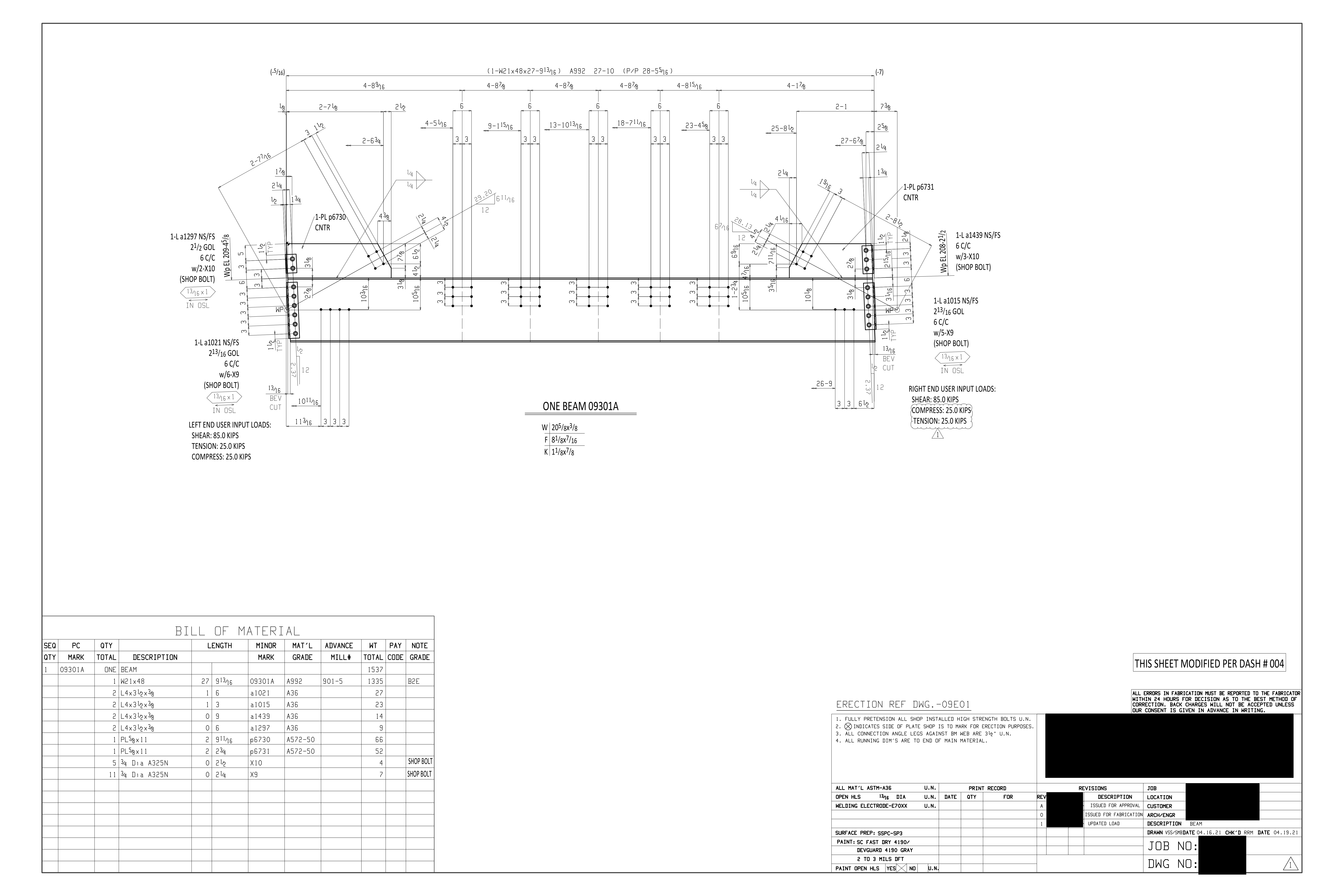

- Shop drawings are essential documents that provide detailed information for the fabrication of steel components. These drawings contain comprehensive data about each structural member, including dimensions, hole placements, bolt specifications, material grades, welding details and any additional connection materials. They also include project details, piece sequencing, surface preparation requirements, and notes for fabricators.

Fabricators rely on these drawings to accurately prepare individual steel pieces and facilitate their shipment.

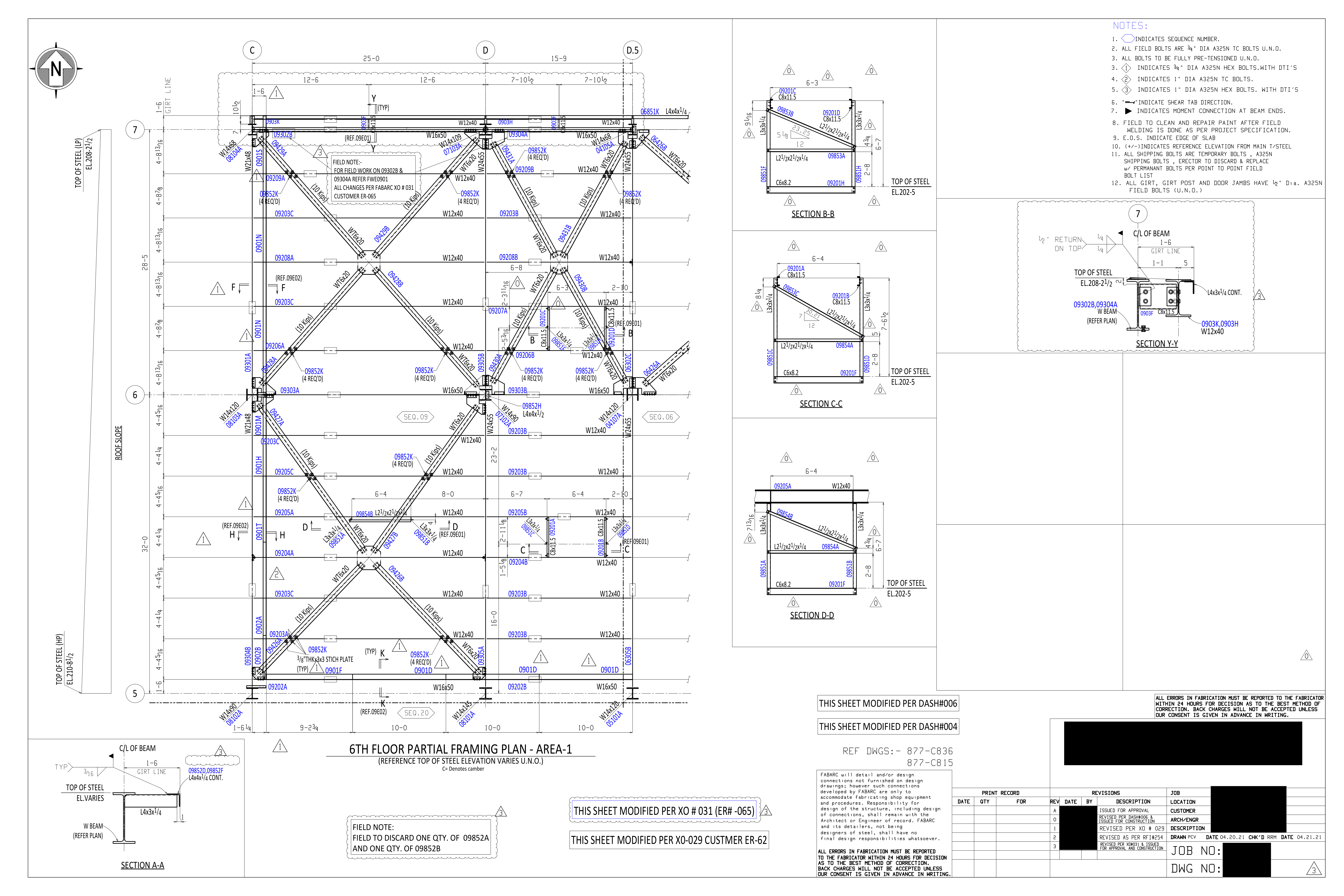

- An erection drawing provides a detailed depiction of the arrangement and positioning of every structural member outlined in the shop drawings. These drawings present the structural layout in both plan and elevation views, accompanied by specific erection notes tailored for the erector’s guidance. These notes may include directives regarding the sequence of erection, such as prioritizing the assembly of certain pieces before others. Additionally, erection drawings highlight any necessary field welding and indicate the locations of non-standard bolts for the erector’s reference.

Components in structural steel detailing

Structural steel detailing involves detailing various components that make up a steel structure. These components include beams, columns, braces, trusses, and connections. Each component is accurately detailed to specify dimensions, shapes, material grades, and connection details. Various factors such as the load-bearing capacity, structural stability, material specifications, and adherence to industry standards are also taken into account. Detailing these components ensures the structural integrity, safety, and efficiency of the final structure.

Tools and software used in detailing

Structural steel detailing relies heavily on advanced tools and software to streamline the detailing process and enhance productivity. Most commonly used software’s are Tekla and SDS2. Additionally, Building Information Modeling (BIM) software provides a collaborative platform for sharing and coordinating design information among project stakeholders. We at Om steel solutions, use SDS 2, a comprehensive detailing solution designed specifically for the steel industry. SDS 2 offers a range of features tailored to the needs of steel detailers, including 3D modelling, automated connections, and advanced clash detection. With its intuitive interface and powerful tools, SDS 2 helps detailers streamline the detailing process, reduce errors, and deliver high-quality detailing solutions for construction projects.

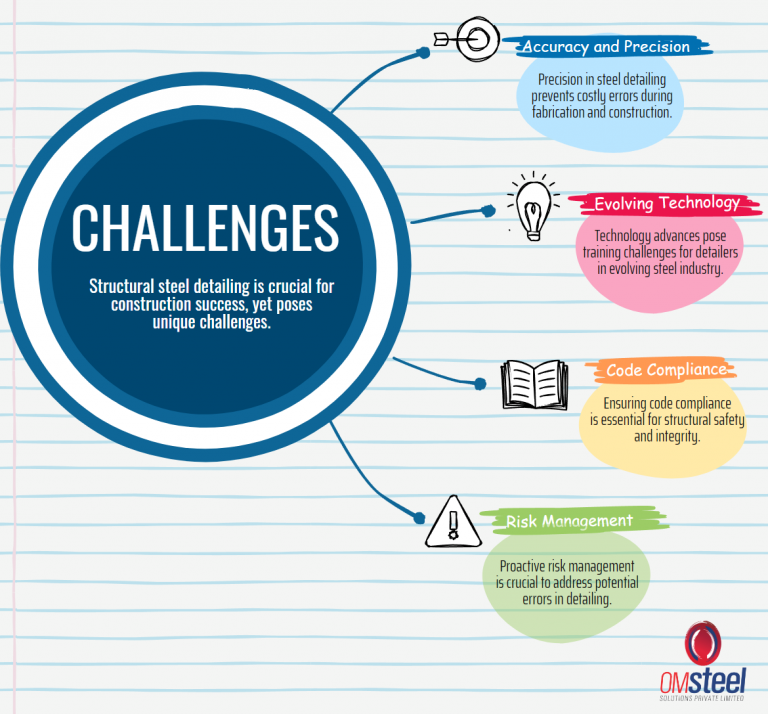

Challenges in structural steel detailing

Structural steel detailing is highly essential for successful execution of construction projects, but it also comes with its own set of challenges. Following are some of the most common challenges faced by steel detailers:

- Accuracy and precision: Even the slightest mistake in the detailing process can result in significant errors during fabrication and construction, leading to costly and time-consuming adjustments. Shop drawings form the cornerstone of steel component fabrication, providing the blueprint for manufacturing. Any inaccuracies within these drawings can introduce errors during fabrication, potentially leading to misaligned or non-compliant structural elements. Additionally, accurate detailing facilitates efficient material usage, optimizing project costs and resources.

- Evolving Technology: The rapid advancement of technology, including Building Information Modeling (BIM) and computer-aided design (CAD) software, presents both opportunities and challenges for detailers. Keeping up with the latest tools and techniques requires ongoing training and skill development.

- Code Compliance: It is paramount that a detailer’s designs comply with all the relevant building codes, industry standards and regulations. This can be a bit tedious, but is essential to ensure the safety and integrity of the structure.

- Risk management: Anticipating and addressing potential risks during the detailing process, such as design, fabrication, or construction errors, is imperative for detailers. Engaging in proactive risk management is crucial for reducing interruptions and achieving project success.

Steel detailers play a pivotal role in ensuring the accuracy, efficiency, and safety of steel structures through meticulous detailing and documentation. By understanding the key components of steel detailing, the importance of accuracy, and leveraging advanced tools and software, steel detailers can contribute to the successful execution of construction projects.

This blog post has provided a glimpse into the world of structural steel detailing, shedding light on its significance and the tools and techniques employed by steel detailers. As the construction industry continues to evolve, the role of structural steel detailing will remain indispensable in shaping the built environment for generations to come.