When you look up at the roof of a warehouse, gymnasium, or bridge, you’re likely seeing the elegant engineering of steel trusses at work. These triangulated frameworks are an important part of structural engineering, efficiently spanning large distances while carrying substantial loads. Let’s dive into what makes trusses so special and how the American Institute of Steel Construction (AISC) ensures they’re designed safely and effectively.

What exactly is a Truss?

Think of a truss as a structural puzzle made of triangles. Unlike a simple beam that bends under load, a truss distributes forces through a network of connected members, with each triangle maintaining its shape and transferring loads efficiently. This triangular geometry is what gives trusses their incredible strength-to-weight ratio.

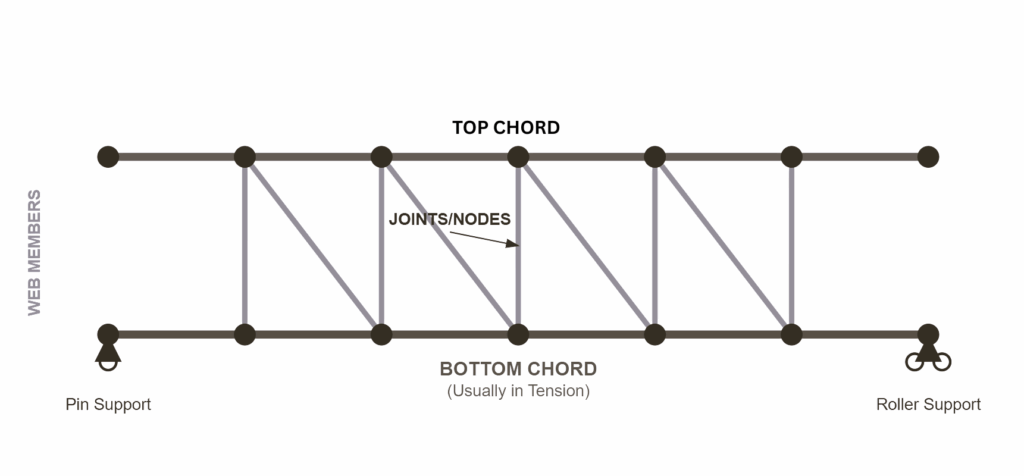

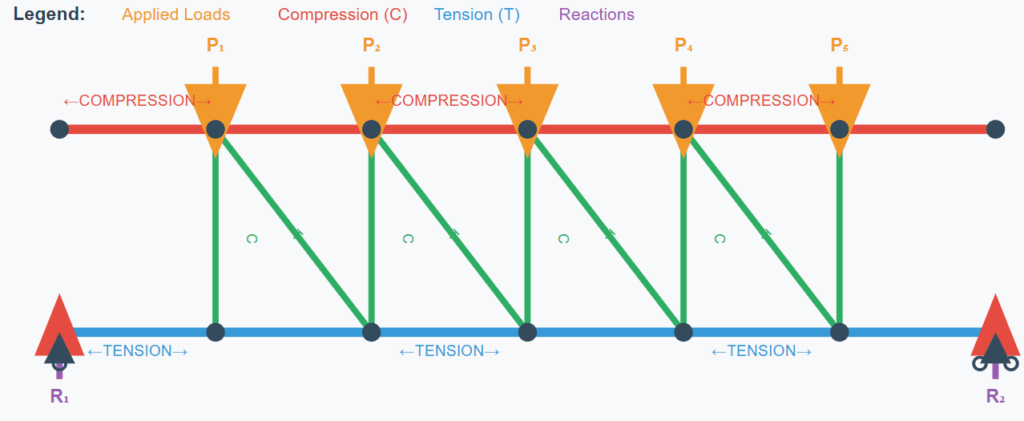

The basic anatomy of a truss includes:

- Top chord: The upper horizontal member that typically experiences compression

- Bottom chord: The lower horizontal member that usually handles tension forces

- Web members: The diagonal and vertical elements connecting the chords

- Joints (nodes): Connection points where members meet, typically assumed to be pinned in analysis

Types of Steel Trusses in AISC Practice

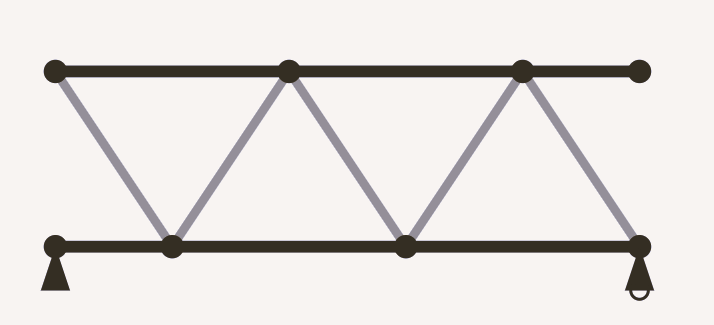

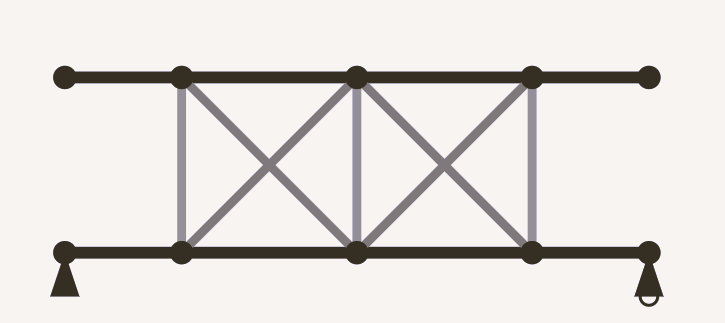

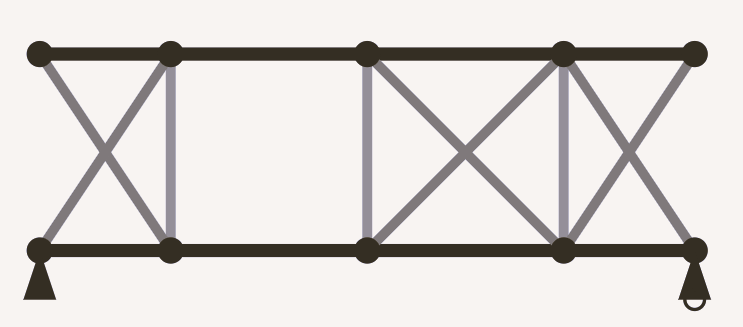

The AISC standards recognize several common truss configurations, each suited for different applications:

Simple Span Trusses: These include Warren trusses (with diagonal members forming a zigzag pattern), Pratt trusses (with vertical members and diagonals sloping toward the center), and Howe trusses (diagonals sloping away from center). Each type offers different advantages in terms of fabrication, material efficiency, and load distribution.

Cantilever Trusses: Extended beyond their supports, these are perfect for creating overhangs or supporting balconies without intermediate columns.

Continuous Trusses: Spanning multiple supports, these systems are highly efficient for long-span applications like bridges or large industrial buildings.

AISC Design Philosophy: Safety Meets Efficiency

The AISC approach to truss design follows the Load and Resistance Factor Design (LRFD) method, which provides a systematic way to ensure structural safety. This method considers both the loads a structure will face and the capacity of materials to resist those loads, applying appropriate safety factors to account for uncertainties.

Load Considerations

Trusses must be designed for various load combinations including:

- Dead loads: The weight of the structure itself

- Live loads: Occupancy, snow, and other variable loads

- Wind loads: Critical for roof trusses and exposed structures

- Seismic loads: Earthquake forces in applicable regions

Member Design Principles

Each truss member is designed according to its primary function:

Tension Members: These are relatively straightforward to design, with the main concern being the net section area at connections and the potential for fatigue under repeated loading.

Compression Members: More complex due to buckling considerations. The AISC specifications provide detailed methods for calculating the buckling capacity based on member slenderness ratios and end conditions.

Combined Forces: Some members may experience both axial forces and bending moments, requiring more sophisticated analysis methods outlined in the AISC specifications.

Connection Design: Where It All Comes Together

Connections are perhaps the most critical aspect of truss design. The AISC standards provide comprehensive guidance for various connection types:

Bolted Connections: Most common in modern construction, offering reliability and ease of inspection. High-strength bolts in slip-critical applications are often specified for critical connections.

Welded Connections: Provide excellent strength and stiffness but require careful quality control and inspection procedures as outlined in the AWS (American Welding Society) standards referenced by AISC.

Practical Design Considerations

Deflection Control

While strength is paramount, serviceability is equally important. AISC provides guidelines for limiting deflections to ensure proper building performance and occupant comfort. Typical limits range from L/240 to L/360 for live loads, depending on the application.

Vibration Concerns

Long-span trusses can be susceptible to vibration issues, particularly in floor systems. The AISC specifications include provisions for addressing human-induced vibrations and other dynamic effects.

Fire Protection

Steel trusses in buildings must often be protected from fire exposure. The AISC guidelines work in conjunction with building codes to determine appropriate fire protection measures.

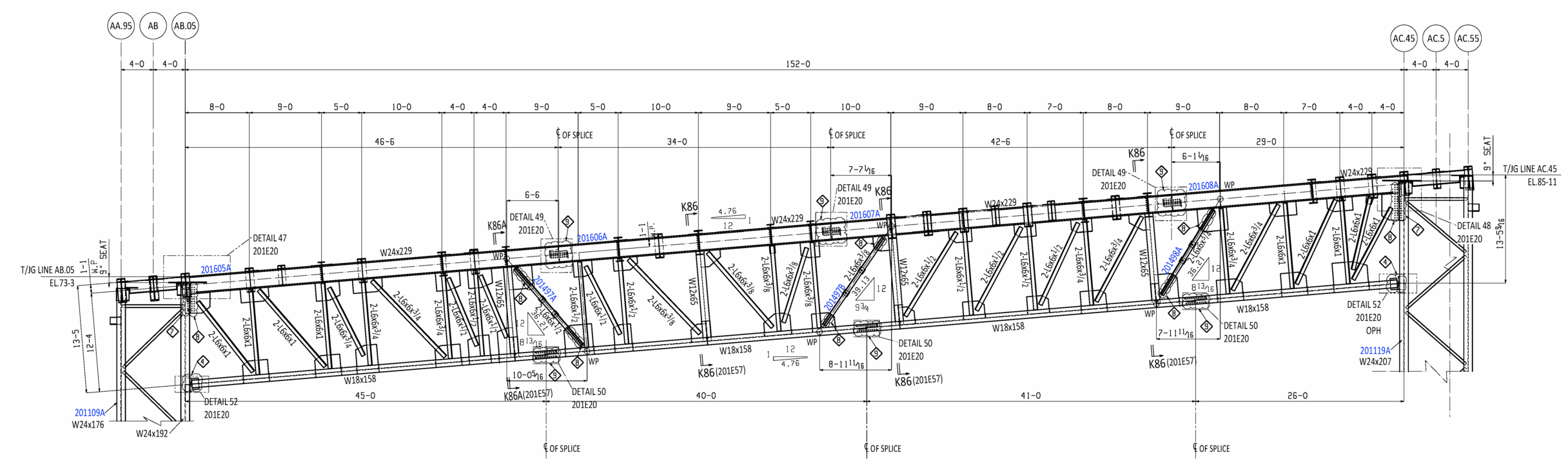

Modern Manufacturing and Erection

Today’s steel trusses benefit from advanced manufacturing techniques. Computer-controlled cutting and drilling ensure precise fabrication, while Building Information Modeling (BIM) helps coordinate complex projects. The AISC Code of Standard Practice provides guidance for fabrication tolerances and erection procedures.

The Future of Truss Design

As construction technology evolves, so do AISC standards. Recent updates have incorporated lessons learned from major projects and advances in materials science. High-performance steels, improved connection technologies, and more sophisticated analysis methods continue to push the boundaries of what’s possible with steel trusses.

Steel trusses represent a perfect marriage of engineering theory and practical construction needs. The AISC standards ensure that these elegant structures perform reliably throughout their service lives, protecting both the people who use the buildings and the professionals who design them. Whether you’re a student just beginning to understand structural engineering or a practitioner looking to refresh your knowledge, appreciating the depth and sophistication of modern truss design standards helps us build better, safer structures for everyone.

Understanding these principles isn’t just about following code; it’s about appreciating the careful balance of safety, economy, and performance that makes modern construction possible.