In structural steel design, the AISC Specification classifies connections into two primary categories: simple connections and moment connections. Moment connections are further divided into:

● Fully Restrained (FR) – Also known as “rigid-frame” connections, these have sufficient rigidity to maintain the angles between intersecting members.

● Partially Restrained (PR) – These connections allow some degree of rotation, providing flexibility in the structural system.

When a design does not require rotational restraint, a simple shear connection is used. These connections are designed to transfer gravity loads through shear while allowing beam-end rotation.

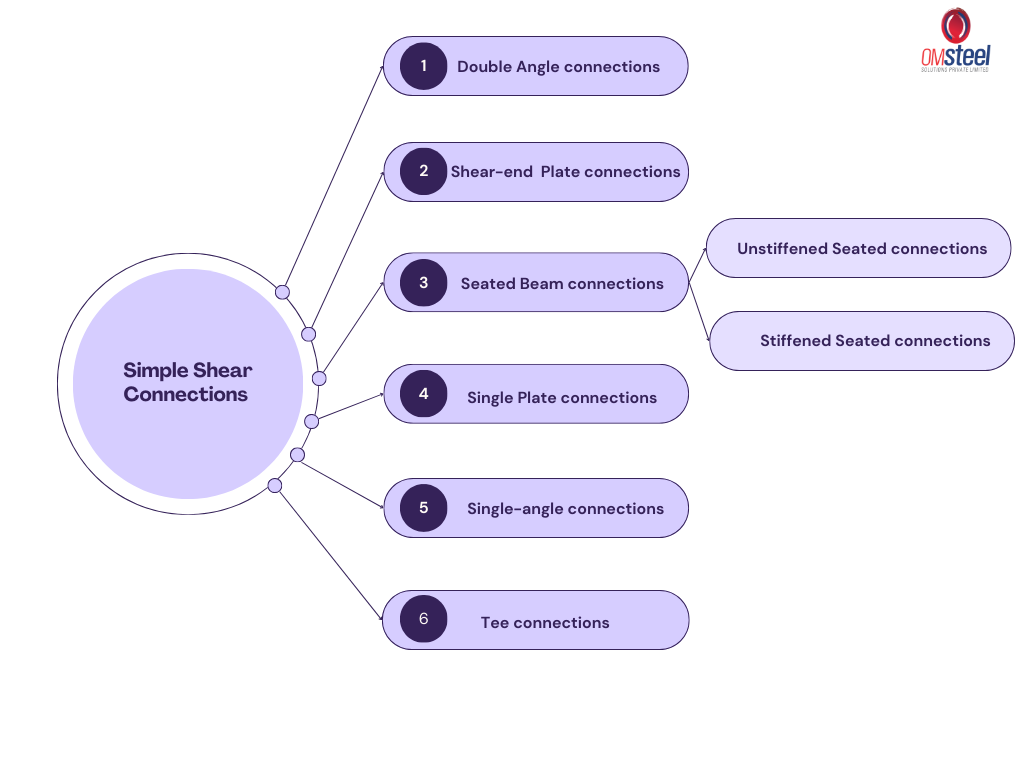

Types of Shear Connections

There are seven primary types of simple shear connections, primarily using high-strength bolts:

Some of these connections—such as shear end-plates, stiffened seats, and single-plate connections—require both welding and bolting to effectively transfer factored loads from beams to supporting members. Others, including double-angle, unstiffened seat, single-angle, and tee connections, may utilize a combination of bolts and welds for a secure connection.

Lets look deeper into all the primary types of shear connections.

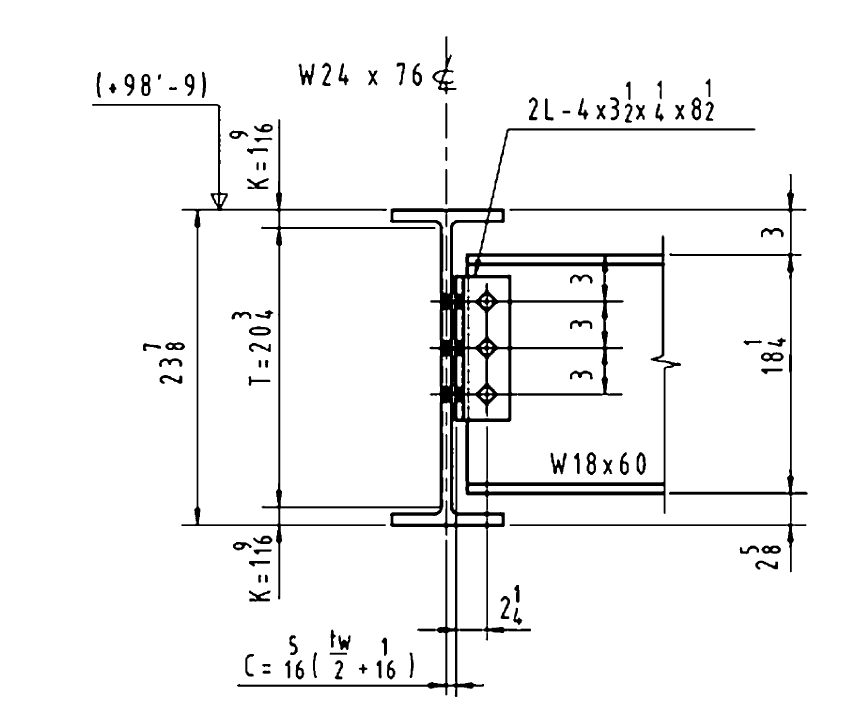

1. Double angle connections

Double-angle connections are highly versatile due to their customizable components, including angle thickness, leg width, fastener and weld sizes, and material type. These connections primarily resist shear forces from gravity loads and also provide good torsional resistance against twisting forces.

When axial loading is present, double-angle connections perform well under axial compression, though this often requires thicker angles than standard framing connections. However, their resistance to axial tension is moderate unless the angles are adequately stiffened or thickened.

The rigidity of a double-angle connection depends on factors such as angle length, fastener size, and location. Even with a minimal number of fasteners, these connections often exceed the required design strength, making them an efficient but sometimes over-designed choice.

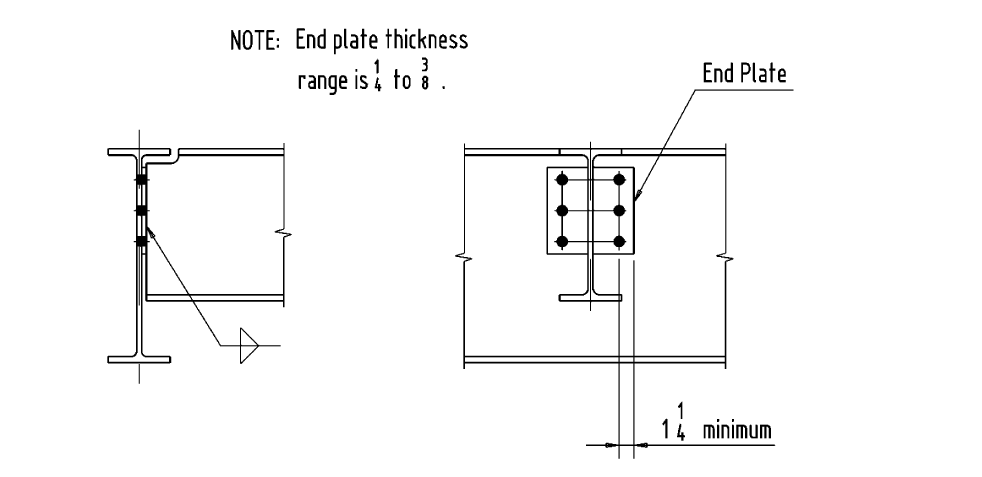

2. Shear-end plate connections

Shear end-plate connections are primarily used to resist gravity loads while allowing the rotational flexibility required for simple shear connections. These connections typically use 1/4- to 3/8-inch-thick plates, which provide good axial compression resistance but are usually unsuitable for axial tension unless specifically designed for it.

The end plate is fillet-welded to the beam and can be either field-bolted or field-welded to the supporting member. When field welding is used, erection bolt holes should be provided.

While some fabricators prefer end-plate connections for their accuracy and ease of adaptation, others find them challenging because beams must be cut square on both ends with precise length. Additionally, beam camber can be problematic unless a shallow end-plate is used. In cases where beams are fabricated slightly short for erection purposes, shims may be needed to maintain building dimensions.

Shear end-plate connections are commonly used for filler beams but can also connect beams to columns and be adapted for skewed members. The plate can accommodate standard holes or horizontal short slots for flexibility in assembly.

3. Seated Beam Connections

Seated beam connections are classified into two main types:

- Unstiffened seated connections

- Stiffened seated connections

These connections are particularly effective for attaching beams to column webs due to their ease of erection and safety benefits, as they do not require common bolts through the column web. They can also be used to connect beams to girder beams, provided the girder depth allows for it. While less common, seated connections can also attach beams to column flanges, as long as they do not interfere with fireproofing or architectural finishes.

Advantages of Seated Beam Connections

Compared to double-angle connections, seated connections offer several benefits:

● They allow for plain punched beams, simplifying fabrication.

● They provide a stable resting point for beams during installation, helping with alignment.

● They offer better erection clearance, especially when connecting beams to column webs.

● For larger beams, seated connections reduce the number of required field bolts, making them more economical.

How Seated Connections Work

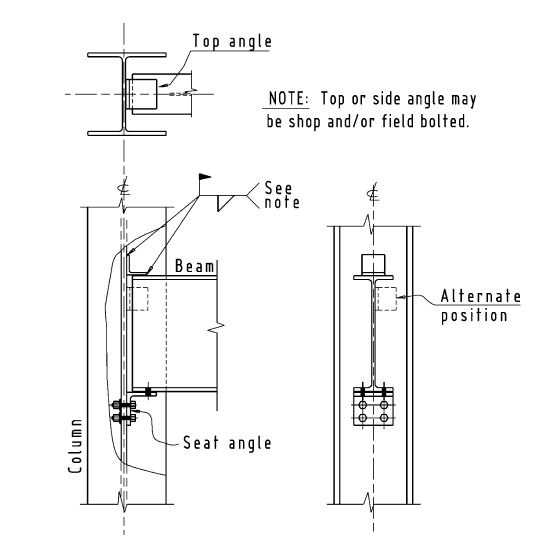

The beam’s end reaction is primarily supported by the seat angle or seat plate. A top (or “cap”) angle is added to provide lateral stability at the beam’s top flange. If attaching the angle to the flange is impractical, it can be connected to the beam web as close to the top flange as possible.

The top angle does not resist shear or moment forces but plays a key role in stability. It is typically installed after the structure is plumbed but before additional loads are applied. Additionally, the beam web’s strength must be evaluated for web crippling and local yielding, making its thickness an important design factor.

1) Unstiffened Seated Connections

Unstiffened seated connections are commonly used to support beams on column webs. In this setup, the beam end is typically kept ½ inch short of the supporting member’s face.

Key features include:

● A seat angle with a 4-inch-wide outstanding leg, providing a 3½-inch bearing length along the supported beam’s web.

● If the required bearing length exceeds the seat’s strength, a stiffened seat connection must be used instead.

● The specific design for unstiffened seats with longer bearing lengths or higher end reactions should be provided on the design drawings.

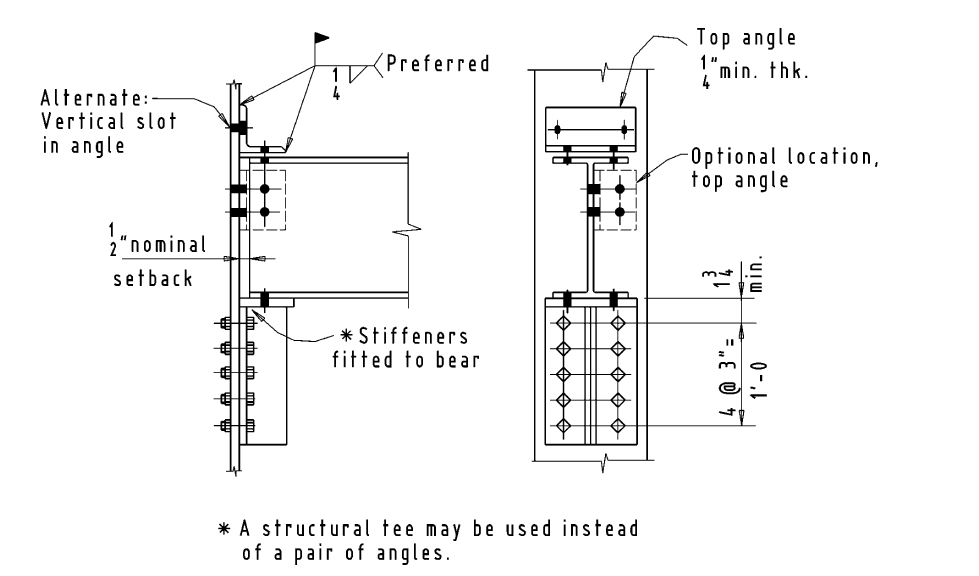

2) Stiffened Seated Connections

When a beam’s reaction force exceeds the bearing strength of an unstiffened seat, a stiffened seated connection is required. In this case, stiffeners are added to bear directly against the underside of the seat plate.

Key considerations for stiffened seats:

● The bearing strength of the connected material and fastener capacity must be evaluated.

● Compressive stress in the beam web directly above the seat plate must be checked.

● The width of the stiffener’s outstanding leg and bearing length should ensure that the beam web’s compressive strength does not exceed its local web yielding or crippling capacity.

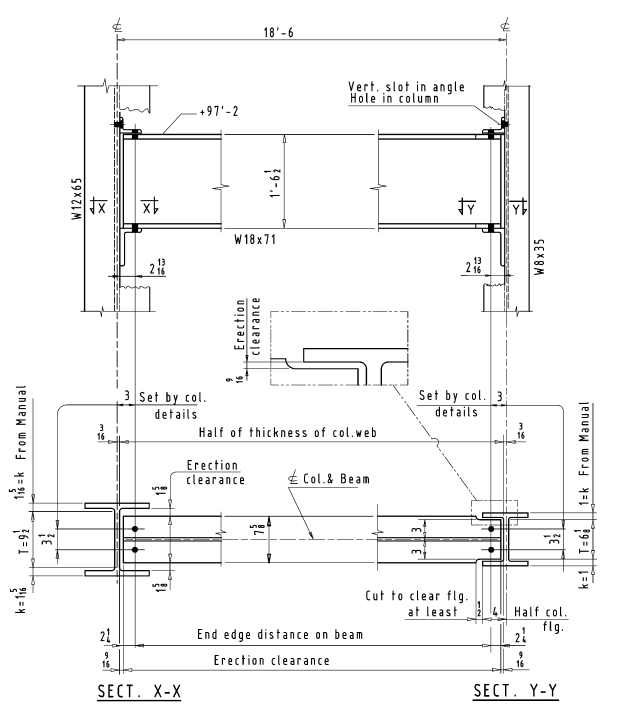

4. Single-plate connections

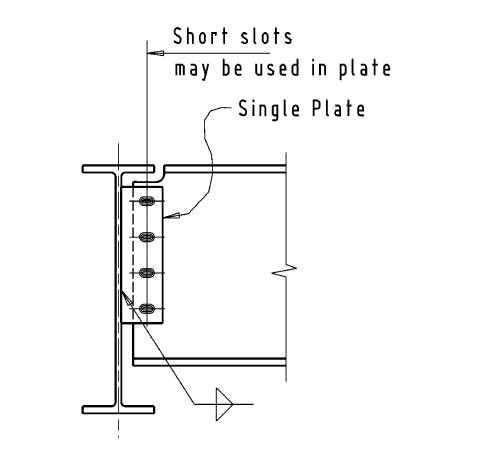

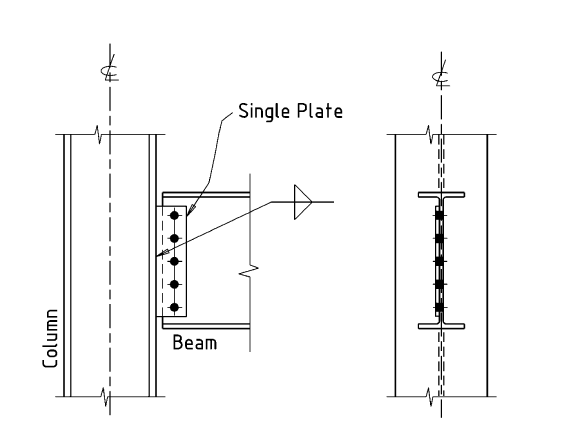

A single-plate connection consists of a plate that is shop-welded to a supporting member, such as a beam or column, and then field-bolted to the supported member. This type of connection is primarily used to resist gravity shear loads, but it can also handle axial compression and tension loads to some extent. However, it is not suitable for connections to column webs due to difficulties in accessing and tightening bolts, reaming if required, and pretensioning bolts when necessary.

While single-plate connections require more bolts than double-angle connections due to the web bolts being in single shear, they remain economical to fabricate and safe to erect in most structural configurations. The rigidity of this connection is moderate and depends on factors such as the number of bolts, their size, and the overall depth of the connection. These connections are highly adaptable, making them useful for skewed or sloped applications.

In cases where single-plate connections are used in beam-to-column web applications where the column web is stiffened, special attention must be given to clearances to facilitate field erection. This is because the field connection must allow enough space for bolts to be installed away from the column flange edges. Additionally, when this type of connection is used for girder web connections, eccentricities larger than normal gages can become a concern, requiring careful design considerations to ensure stability.

5. Single-angle connections

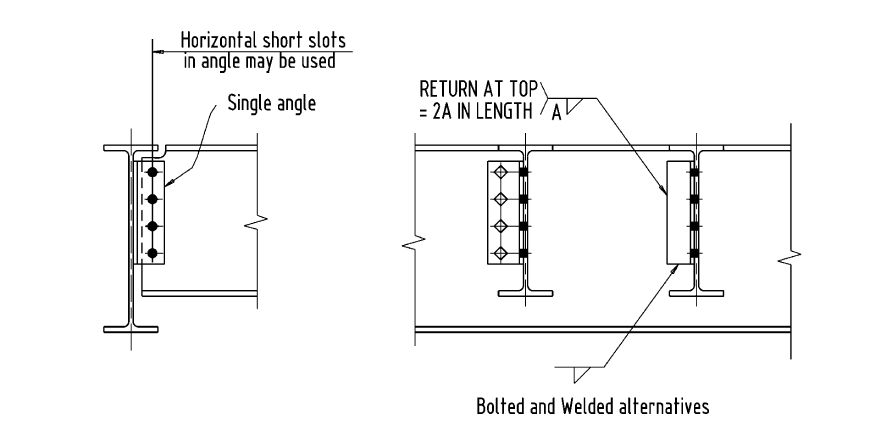

Single-angle connections serve a function similar to single-plate connections but offer specific advantages in terms of erection simplicity. They are primarily used to resist gravity shear loads and are one of the most flexible connection types, making them ideal for simplifying construction. Their fabrication is economical, and they provide safe erection in almost all configurations. However, single-angle connections have poor torsion resistance and should not be used in applications where torsional loads are present. Additionally, they are not suitable for resisting axial tension loads due to their flexibility.

For efficient installation, the standard practice is to shop-weld or bolt the angle to the supporting member. Connecting the angle to the supported member in the shop can make field erection more difficult, so it is usually avoided. The field connection is then made by bolting through the angle leg into the web of the supported beam. To accommodate fabrication and erection tolerances, horizontal short slots can be used in the field-connected leg. These slots also help account for beam end rotation in cases where cambering is present.

Compared to double-angle connections, single-angle connections are more convenient in situations where space constraints make it difficult to use double angles. They also allow for better clearance during erection, making them a preferred choice in certain structural arrangements.

6. Tee Connections

Tee connections are primarily used for shear connections and are typically fabricated by cutting a tee from a W or HP shape or by welding two plates together, which is particularly useful for skewed connections. Only W and HP shapes that meet specific criteria, such as web and flange thickness, flange width, and other dimensional requirements, are suitable for use as tee connections.

For stability during erection, it is recommended that the tee has a minimum length equal to at least half the T-dimension of the supported beam. The maximum length should be compatible with the T-dimension of an uncoped beam or the remaining web depth of a coped beam, excluding fillets. To allow for the necessary flexure that accommodates beam-end rotation, the flange thickness of the tee should be kept minimal unless the tee stem is specifically designed to meet the strength requirements of a single-plate connection.

Tee connections offer good resistance to axial compression loads in the beam but are relatively weak in resisting axial tension. They provide fair resistance to torsion, even when using the shortest permissible tee length for the beam web. Typically, the tee is shop-attached to the supporting member, though in rare cases, it may be shop-attached to the supported beam. However, this latter method reduces some of the practical benefits of a tee connection. The connection to the supporting member can be achieved through bolting or welding, and both standard round holes and horizontal short slots can be used in the flange and web of the tee.

Although tee connections are safe and quick to erect, they are not the most economical option due to the additional shop work required for preparation.

Steel connections play a crucial role in ensuring the stability, strength, and efficiency of a structure. Each connection type—whether double-angle, shear end-plate, seated beam, single-plate, single-angle, or tee connections—has distinct advantages and applications based on the design requirements. Some offer versatility and ease of erection, while others provide superior shear, axial, or torsional resistance. Selecting the right connection depends on factors such as load conditions, fabrication efficiency, field conditions, and overall structural integrity.

By understanding the characteristics and limitations of each connection type, engineers and detailers can optimize designs for both performance and cost-effectiveness. Properly designed and detailed connections not only enhance the safety and durability of steel structures but also improve the efficiency of fabrication and erection, ultimately contributing to a well-executed and structurally sound project.