In the world of structural steel, precision in detailing is what turns conceptual engineering into constructible reality. Whether it’s placing a girt clip at the right elevation or coping a flange for a clean fit, each component tells a story of stability, economy, and buildability. This post walks through several commonly used steel construction elements from girts and sag rods to shear studs and stiffeners with a focus on their functionalities, purpose and installation.

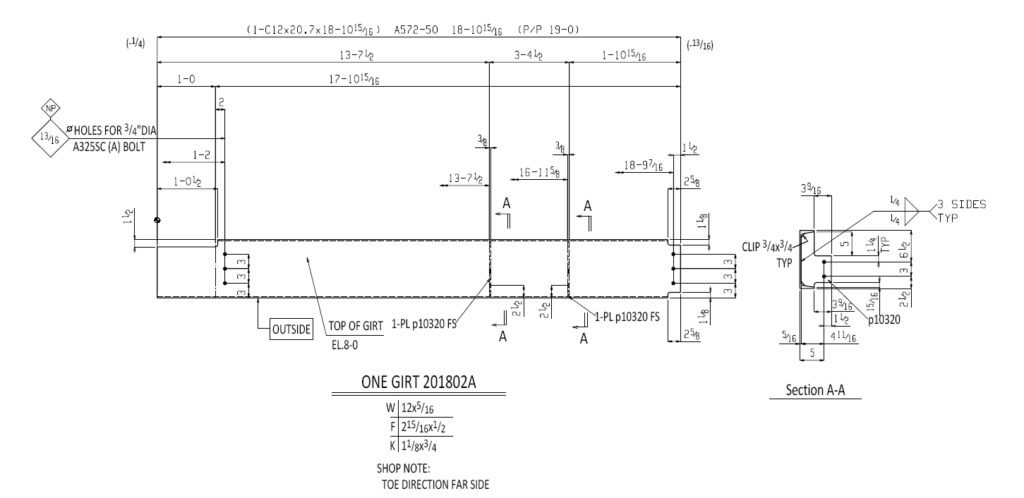

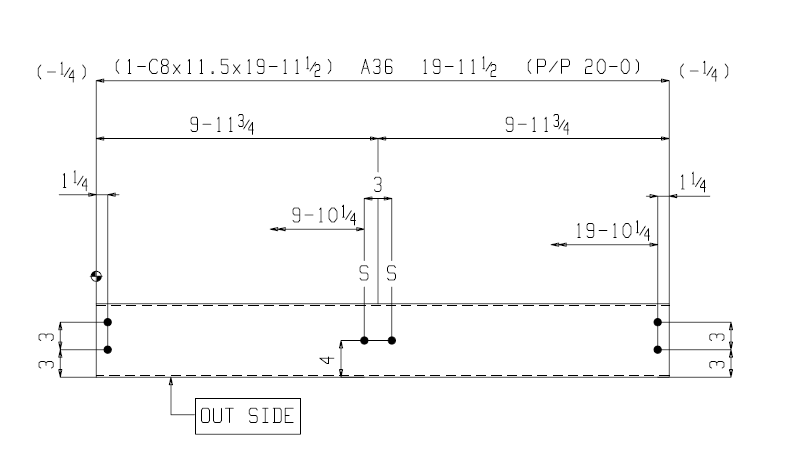

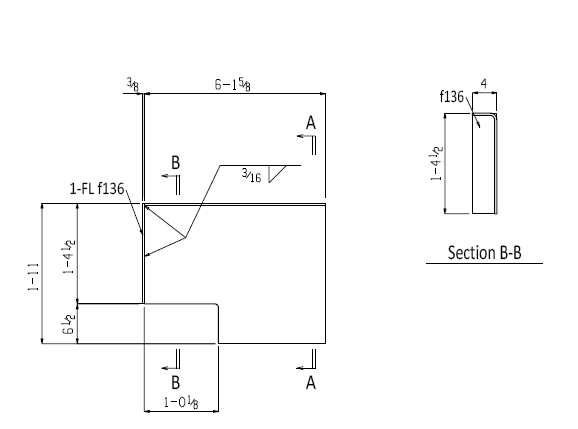

Girts

Girts are horizontal structural members affixed to columns, providing lateral support to wall panels in steel-framed buildings. They play a pivotal role in transferring wind and other lateral loads from the wall sheathing to the primary structural frame.

Key Points:

- Functionality: Their main function is to support wall cladding and transfer lateral loads.

- Installation: Typically connected to columns using clips; girts are often made from C or Z-shaped cold-formed steel sections.

- Orientation: Flanges are usually oriented downward to prevent accumulation of debris.

- Corner Connections: Proper detailing at building corners is crucial to accommodate differential movements and prevent distress in corner flashings.

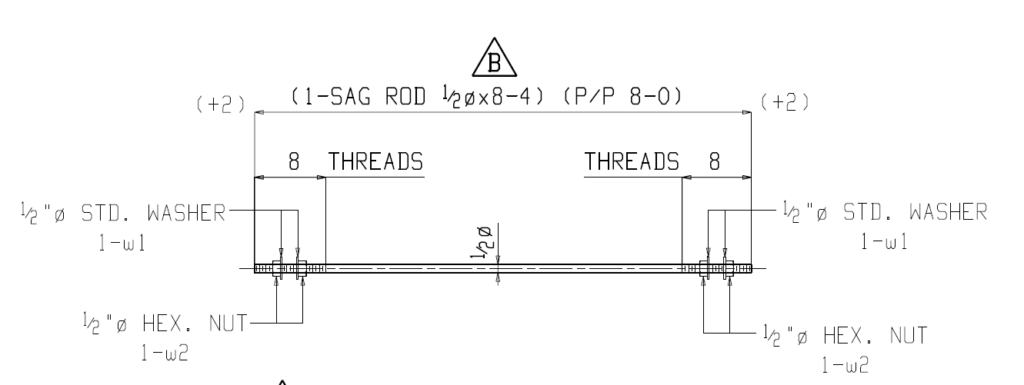

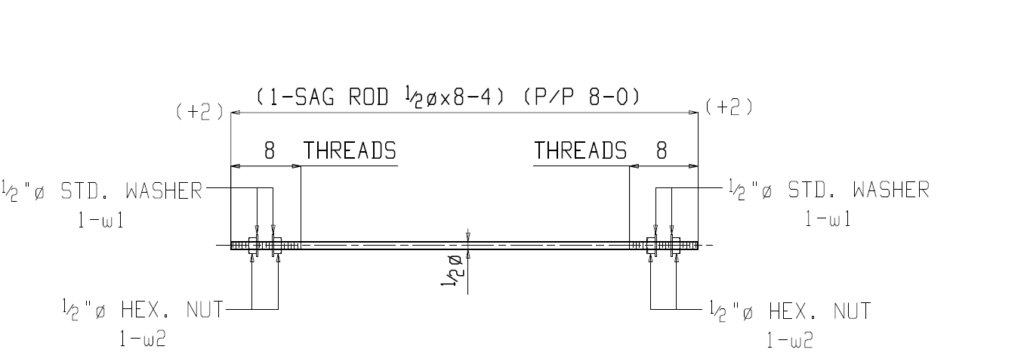

Sag Rods

Sag rods are tension members installed between girts to prevent sagging due to gravity and wind loads, ensuring the structural integrity of wall systems.

Key Points:

- Purpose: Sag rods maintain alignment and reduce deflection in girts.

- Installation: Typically threaded rods with nuts and washers on both ends; may include double nuts for enhanced stability.

- Placement: Sag rods are installed vertically or diagonally between girts at specified intervals.

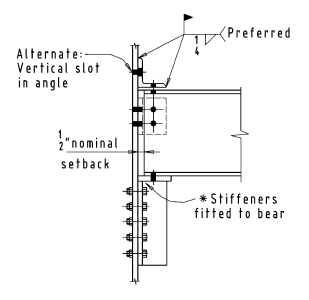

Bent Plates

Bent plates are L-shaped steel elements used primarily as pour stops at the edges of concrete slabs, preventing concrete from spilling over during pouring. They also define floor openings and support edge conditions.

Key Points:

- Purpose: Base plates act as a formwork for slab edges and openings.

- Installation: They are either welded or bolted to the top flange of perimeter beams.

- Additional Uses: Base plates can serve as attachment points for façade elements or edge protection systems.

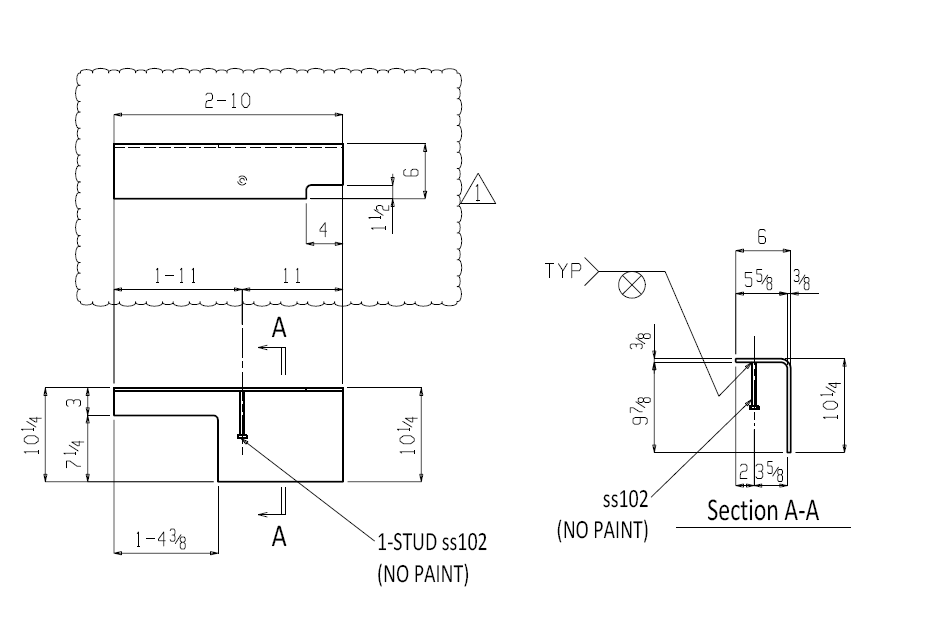

Shear Studs

Shear studs are headed steel studs welded to steel beams, enabling composite action between the steel and concrete in floor systems. They ensure the two materials act together to resist loads.

Key Points:

- Functionality: Shear studs transfer shear forces between steel beams and concrete slabs.

- Installation: They are typically welded through metal decking into the beam’s top flange before concrete pouring.

- Design Considerations: The spacing and size needed, depend on load requirements and slab thickness.

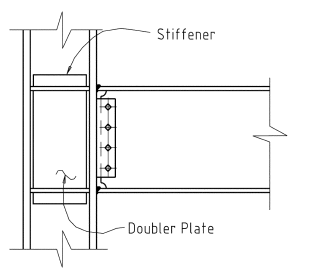

Stiffeners:

Stiffeners are plate elements welded to beams or columns to prevent local buckling and enhance load-carrying capacity, especially at points of concentrated loads or reactions.

Key Points:

- Types: Bearing stiffeners (at supports) and intermediate stiffeners (along the member length).

- Installation: Welded perpendicular to the web of beams or columns; must clear the ‘k’ area to avoid interference with flange-to-web transitions.

- Design Considerations: Thickness and size are determined based on the magnitude of loads and member dimensions.

Web Doublers:

Web doublers are additional plates welded to the web of beams or columns to increase their shear capacity, especially in areas with high shear demands or where openings reduce the effective web area.

Key Points:

- Purpose: Strengthen the web to resist increased shear forces.

- Installation: Welded to one or both sides of the web, depending on design requirements.

- Design Considerations: Thickness and extent are based on the required shear reinforcement; welding must ensure proper load transfer.

Understanding the roles and proper implementation of these steel construction components is crucial for the integrity and longevity of structures. From supporting wall systems with girts and sag rods to ensuring composite action with shear studs, each element contributes significantly to the overall performance of a building. Proper detailing, installation, and maintenance of these components are essential for achieving structural efficiency and safety.